The Process

1 Simply put, polishing concrete is similar to sanding wood. Heavy-duty polishing machines equipped with progressively finer grits of diamond-impregnated segments or disks (akin to sandpaper) are used to gradually grind down surfaces to the desired degree of shine and smoothness.

2 The process begins with the use of coarse diamond segments bonded in a metallic matrix. These segments are coarse enough to remove minor pits, blemishes, stains, or light coatings from the floor in preparation for final smoothing. Depending on the condition of the concrete, this initial rough grinding is generally a three- to four-step process. With this process we give the floor a smooth profiile.

3 The next steps involve fine grinding of the concrete surface using diamond abrasives embedded in a plastic or resin matrix. Crews use ever-finger grits of polishing disks (a process called “lapping”) until the floor has the desired sheen. For an extreme- ly high-gloss finish, a final grit of 1500 or finer may be used. Experienced polishing crews know when to switch to the next-fin- ger grit by observing the floor surface and the amount of material being removed.

CONTACT US

About us

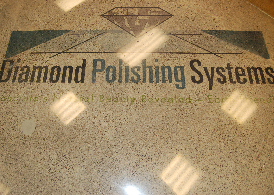

With over 25 years in the floor care industry, Diamond Polishing Systems knows what it takes to make customers happy. Knowing the limitations of conventional floor care systems made the decision easy for us to feature concrete polishing along with our current line of services.

Polished concrete is without a doubt becoming the present and is certainly the future of industrial, commercial, and residential flooring. Incredible gratification comes from producing beautiful long lasting, maintenance free floors that are also very environ- mentally friendly.

Visit our showroom

8801 Canyon Rd E Puyallup WA 98371

(253)770-0508

Servicing all of Washington and select areas of Oregon and Idaho